The flat roof structure is a complete system. It typically consists of a supporting structure, a vapour barrier, insulation, waterproofing and effective ventilation. The supporting structure is usually double-T slab, corrugated steel sheet, reinforced concrete slab or hollow core slab.

Supporting corrugated steel structures

Steel sheets should be 0.65 mm thick or more. Aluminium should be at least 0.9 mm thick. Clean all metal sheets before installing insulation.

| Total insulation thickness, mm |

Joints not on top of profile, max. "a" mm |

Joints on top of profile, max. "a" mm |

For every profile, min. "b" mm |

| 20 |

120 |

120 |

35 |

| 50 |

120 |

170 |

35 |

| 80 |

180 |

220 |

35 |

| 100 |

200 |

- |

35 |

| 120 |

220 |

- |

35 |

The vapour barrier is a building envelope layer that prevents undesired moist indoor air from entering the construction layers. Implement the vapour barrier with a bitumen membrane or 0.20 mm non-ageing plastic foil. It must be installed as close as possible to the warm inner side of the structure (at least three-quarters of the thermal insulation should be on top of the vapour barrier). If necessary, use a 20 – 70 mm thick stone wool insulation layer as a substrate for the vapour barrier. Pay special attention when sealing vapour barrier penetrations such as roof lights, ventilation ducts and pipes, etc. We recommend that a vapour barrier be used in all kinds of flat roof structures.

When using Paroc stone wool insulation, you don’t choose products based on the supporting structure. Choose the right products based on fire classification, mechanical properties and durability. Insulation slabs act as weight distributing layer, which means that the strength properties of the insulation and roofing material must be compatible.

Flat roofs experience a variety of different loads that you must take into account when choosing insulation products.

Insulation slab stress classes

The compressive stress/strength of thermal insulation slabs is tested according to EN 826 (at 10% deformation or at yield or rupture).

| Use of structure |

Bottom and intermediate layer

|

Top layer |

Stress class R1: (light)

Ordinary storage building

|

PAROC ROS 20 |

PAROC ROB 80(t) |

Stress class R2: (normal)

Ordinary residential or office building

|

PAROC ROS 30(g)

|

PAROC ROB 60(t) |

Stress class R3: (heavy)

Ordinary industrial building

|

PAROC ROS 50(g) or PAROC ROS 60(g)

|

PAROC ROS 80(t)

|

Stress class R 4: (extreme)

Demanding industrial building

|

PAROC ROS 60(g) |

PAROC ROS 80(t)

|

The values above are also valid for covered and grooved slabs.

Use at least two to three mineral wool layers, where the top layer is harder and stiffer. The top layer is also a thinner layer (20 –70 mm). Use grooved slabs so that the grooving is as close to the surface of the insulation (20 –70 mm from the top surface) as possible. When using slab type insulation, stagger the joints staggered and ensured that they do not form a grid pattern.

Insulation slabs and roofing are usually mechanically fixed to the supporting structure due to the wind suction load and other forces that affecting the structure. Each decking material requires its own fixings and fixing methods. Fix membranes to the substrate with bitumen, special mechanical fixings or a combination of these.

Mechanical fixings refer mainly to the use of self-drilling screws in metal, wood or expanding securing devices for concrete/light concrete. The telescope effect of securing devices needs to be at least 20 %. Choose sheet metal screws that are at least 20 mm longer than the thickness of the insulation. The following minimum number of securing points applies:

| Area |

Number/m2* |

Max. distance; both directions (mm) |

Middle zone

|

1 - 2 |

1200 |

Edge zone

|

3 - 4 |

600 |

Corner zone

|

3 - 6 |

600 |

*Calculate based on the membrane type and local wind load.

Choose roofing membranes according to the slope of the roof. Roofing requirements become more stringent as the pitch of the roof gets lower. A sufficient slope ensures a good and economic result.

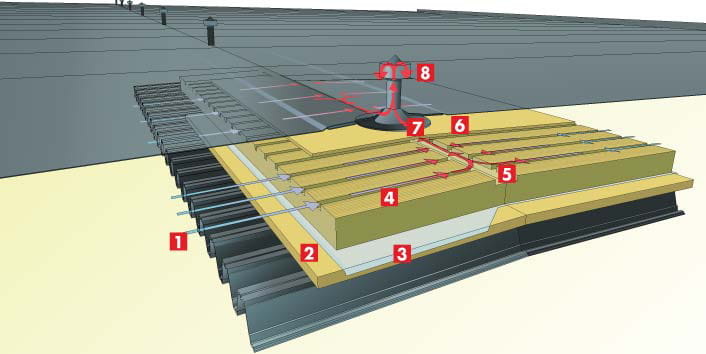

For the ventilated PAROC Air solution, arrange ventilation using suitable low-pressure ventilators in the collecting channels or ventilation gaps in the eaves. The continuous ventilation grooves are directed from the eave to the ridge and they are connected to collector channels at both ends. (More information below.)

Ventilated, moisture-safe flat roof: PAROC Air

This is how the PAROC Air works:

- The movement of the wind forces air up the grooves towards the wider ridge channel.

- 50 mm stone wool slabs protect the vapour barrier and safeguard its effectiveness.

- The vapour barrier consists of a plastic sheet or similar material. It prevents rising warm air from condensing on the membrane. The vapour barrier and junctions with the rest of the structure must be free from leaks. Joints should overlap at least 200 mm, otherwise it can lead to a chimney effect, in which moist air is drawn up and frozen inside the structure in winter. The vapour barrier also eliminates draughts, ensuring that the ventilation system works better throughout the building,.

- Grooved stone wool with high vapour permeability carries moist air along the grooves to the vents. The slab is supplied with 20 mm deep and 30 mm wide grooves. Transverse channels are then cut across the grooves at intersections with items such as roof windows and fire hatches.

- The wider ridge channel, which is cut manually, should be 100 mm wide and 20 mm deep. This channel connects the grooves that run up the slope to the roof vents.

- 20 mm stone wool board helps keep the air in the grooves around 5 degrees warmer than the outside air. This board forms the base for the outer membrane.

- Holes are cut in the board underneath the roof vents.

- Roof vents made of metal or plastic finally lead the moist air outside. The roof vents are installed at 6– 8m intervals along the ridge and at 10– 12 m intervals in valleys. They have a diameter of 100 mm and a height of around 400 mm.

Use non-combustible A1 class insulation material to eliminate the need for separate fire breaks. Stone wool also simplifies hot work on roofs.

Noise reduction of the Paroc roof system

Noise reduction for 20mm PAROC 80 t + 130 mm PAROC ROS 30 on Plannja TRP 200.

Areas with traffic: outdoor decks and terraces / Inverted roofs

In inverted roof systems, falls are ready made in the supporting construction. Install the waterproofing, which also acts as vapour barrier, directly on the roof deck. Install insulation on the top of roofing and cover it with a filter fabric. The final layer, such as a gravel ballast or concrete slab, is heavy enough to keep the insulation in place.

An inverted structure is ideal in many ways: the vapour barrier is always adequate and the roofing membrane is protected from frost, mechanical stress, solar radiation, air pollution and other damaging effects.