Paroc has non-combustible slab insulation and insulation lamellas for almost every type of building from single-family homes or industrial buildings to skyscrapers, from new construction to the renovation of old existing buildings.

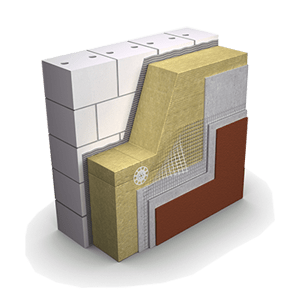

Both stone wool boards for rendered facades can be applied to all common substrate, for example masonry, concrete and timber frame, and are perfectly suited for individual façade design with render, clinker or natural stone and claddings.

Thanks to their high-performance specification, they can meet all current international energy-saving standards in the building industry, while protecting occupants in the event of a fire due to their non-combustibility.

PAROC Stonewool is fire resilient, moisture resistant and sound absorbing insulation material, and is therefore suitable for rendered facade (ETICS) insulation in all common type of building, substrate and facade design.