General

The substrate must be clean, sufficiently dry, and flat before starting to install the insulation slabs.

The corresponding instructions of the system supplier for substrate preparation, adhesive mixing and application must be observed.

Adhesive application methods:

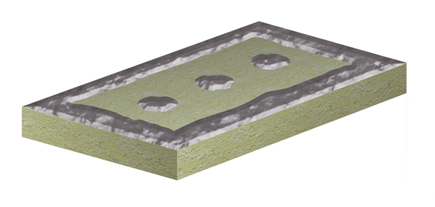

1) Adhesive application for uncoated slabs using the bed/spot method

For partially bed/spot bonding, the adhesive is applied continuously along the edge of the uncoated slab in accordance with the manufacturer's instructions and additional spots of adhesive are placed in the center.

With this type of bonding, unevenness of up to 20mm can usually be compensated. The specifications of the system supplier regarding the contact area between adhesive and substrate surface (in many cases 40%) must be observed.

Bed/spot method adhesive application for uncoated slabs

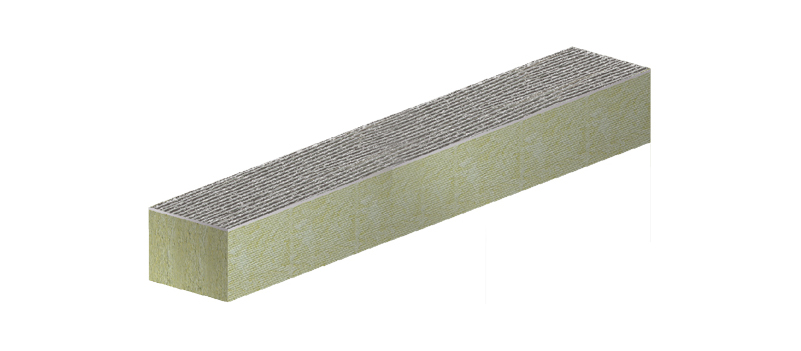

2) Full-surface adhesive application method for uncoated slabs/lamellas

This type of bonding is particularly suitable for even substrates; unevenness of up to 5mm can be compensated with the adhesive.

The adhesive should be applied over the entire surface with a notched trowel; notching must be selected according to the manufacturer's instructions.

Full-surface adhesive application for uncoated slab/uncoated lamella

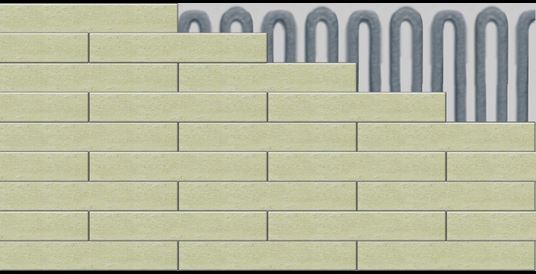

3) Adhesive application for coated slabs/lamellas on the substrate

In case of coated slabs or coated lamellas, the adhesive can either be applied directly to the substrate in “Meander” shape with the machine or to the back of the insulation board (as previously described).

Adhesive application for coated slabs on the substrate

Adhesive application for coated lamellas on the substrate.

Single-layer stone wool slab installation

After applying the adhesive, the insulation slabs are applied to the substrate with a slight sliding movement and then pressed down, preferably with a sanding board.

The slabs are laid from bottom to top and butted tightly in the bond (open joints should generally be avoided)

The installed insulation slabs must be held evenly firm on the substrate to avoid subsequent movement.

Two-layer stone wool slab installation (especially with higher thicknesses):

Two-layer slab installation is recommended when higher thickness is required (up to 400 mm). It is easier to handle with the thinner insulation slabs, because of lower weight. Two insulation layers stagger board joints and significantly minimize risk of thermal bridges.

Two insulation layers should be separated in the middle of the total insulation thickness, if possible.

Slabs can be bonded in both ways mentioned above.

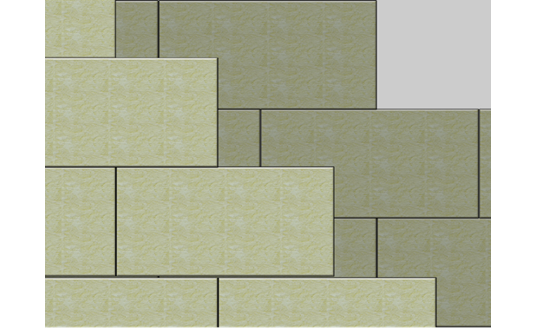

The 2nd layer slabs should be glued to the 1st layer overlapping the joints as it shown in the picture.

The additional dowelling is usually carried out across the complete insulation thickness respectively through both insulation thicknesses.